02

Quality policy

The highest quality and customer focus are ensured by Carpol's DNA. Our culture is built on the commitment and fair participation of each person. Therefore, our partners must ensure the highest standards.

01

We believe that every technological solution must be safe in order to be innovative. That is why all our bodies have been granted the relevant European homologations. Before implementation, we test the strength of the seats, check their fixing points to the floor and make sure that each element we install has the appropriate certificates.

02

The highest quality and customer focus are ensured by Carpol's DNA. Our culture is built on the commitment and fair participation of each person. Therefore, our partners must ensure the highest standards.

03

Opel was the first brand to trust the then small Carpol in 2000. Together we built the first car in Poland for the anti-terrorist brigade. Since 2001, we have been an authorised company that produces the bodies for this car brand. In 2014, we were granted the certificate of the European supplier of bodies for the Opel brand.

Together with Renault, we have completed many successful projects. The openness of the brand and Carpol’s enthusiasm resulted in the creation of cars such as the Status or the Cumulus. Together we have maintained our position as leaders of the bodied cars market.

Carpol was the first company in Poland to receive the Volkswagen Premium Partner certificate. In the same year, we were awarded the title of the best dealer network partner. We nurture our relationship with Volkswagen Group Polska every day.

We have been an authorised partner since 2009 and in 2018, we received the status of Qualified Partner for bodies for delivery vehicles. Every day we are seeing an increase in sales of this brand's cars with our car body.

Our first body was made for Toyota. Our cooperation started in 1997, and exactly 12 years later, we are developing the market of car bodies together, creating new technological solutions.

Iveco is primarily about the experience of bus construction. Thanks to this brand, we have introduced this type of body into our range.

In 2010, we received an authorised car body manufacturing company certificate. Our continuous development enabled us to achieve second place in the production of car bodies on Fiat models in 2018.

We have been working with the Citroën dealer network for over 10 years. We have achieved a great deal, including a contract for more than 1,000 cars for the Polish Post.

We have years of experience with Peugeot in the performance of tenders. Our largest joint project was 80 armoured trucks and 140 cars for Veolia.

In 2018, we received an award for the best cooperation in the implementation of VAN bodies.

We gained Ford's trust already in the 90s and then we made the first bodies for this brand’s vehicles. The official authorisation of the Ford brand was obtained in 2007 and since then we have been expanding together. We operate as an accessory supplier and a body manufacturing company in the field of adaptation of vehicles sealed by Hendry Ford.enrego Forda.

04

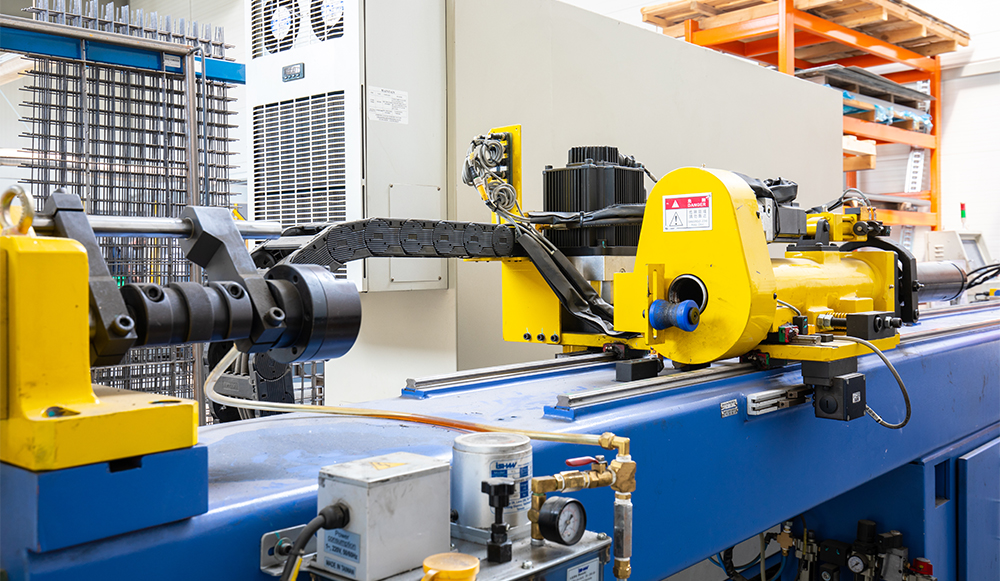

The production process of our bodies is organised. At every stage, we pay attention to quality, hence the emphasis on quality control between operations.

We use five-axis plotters, have our own CNC machining centre and constantly increase our machinery park. It guarantees the high quality of all the elements of our bodies.